CNC Machining

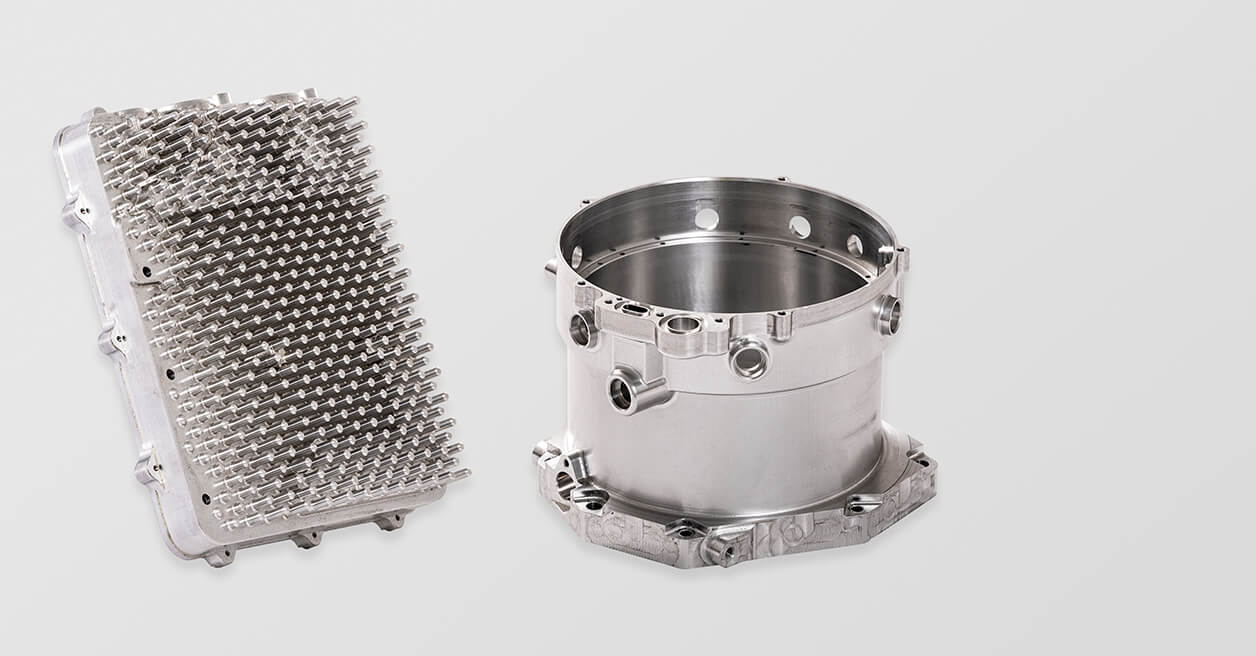

From one-off prototypes to full-scale production, our CNC machining services deliver high-accuracy results for the most demanding applications. We specialize in machining complex geometries from solid stock or castings, working with wide range of materials including metals, plastics, and composites. Whether it’s for automotive, aerospace, medical, defence or industrial use, our precision surface finishing, and ultra-tight tolerance capabilities ensure every component meets the highest standards. With rapid turnaround times and uncompromising accuracy, we deliver parts that are built to perform.